Let’s say you have some conveyors and you need to keep track of the boxes that are in a certain section. Now if you replace the people in the above examples with some kind of data, and you begin to see how this could be used in a PLC programming context. However, the principles are basically the same, so that if you get a handle on the material in this tutorial, I am sure you will be able to figure it out! LIFOs can also be used in Studio 5000, but this tutorial will focus exclusively on FIFOs. Or, if you are the last person to get into a packed subway car, you will be the first one out at the next station. If you stack ten pallets on top of each other, the last one in will necessarily be the first one out. This is often used when items are stored in stacks. There is another way of organizing a queue that simply reverses this arrangement: LIFO or Last-In-First-Out. The order in which the people arrive is the order in which they will be processed.

No matter how fast or slow they are served, or how many people are added to the line, the next person to be served (the next person who will be ‘out’) will always be the one who has been standing the longest (who was ‘first in’). We’ve all encountered this in everyday life picture a single file line of people waiting to order ice cream. This refers to the organizing principle of a queue or list. Understanding FIFOsįIFO stands for First-In-First-Out, or put another way, first-come-first-served.

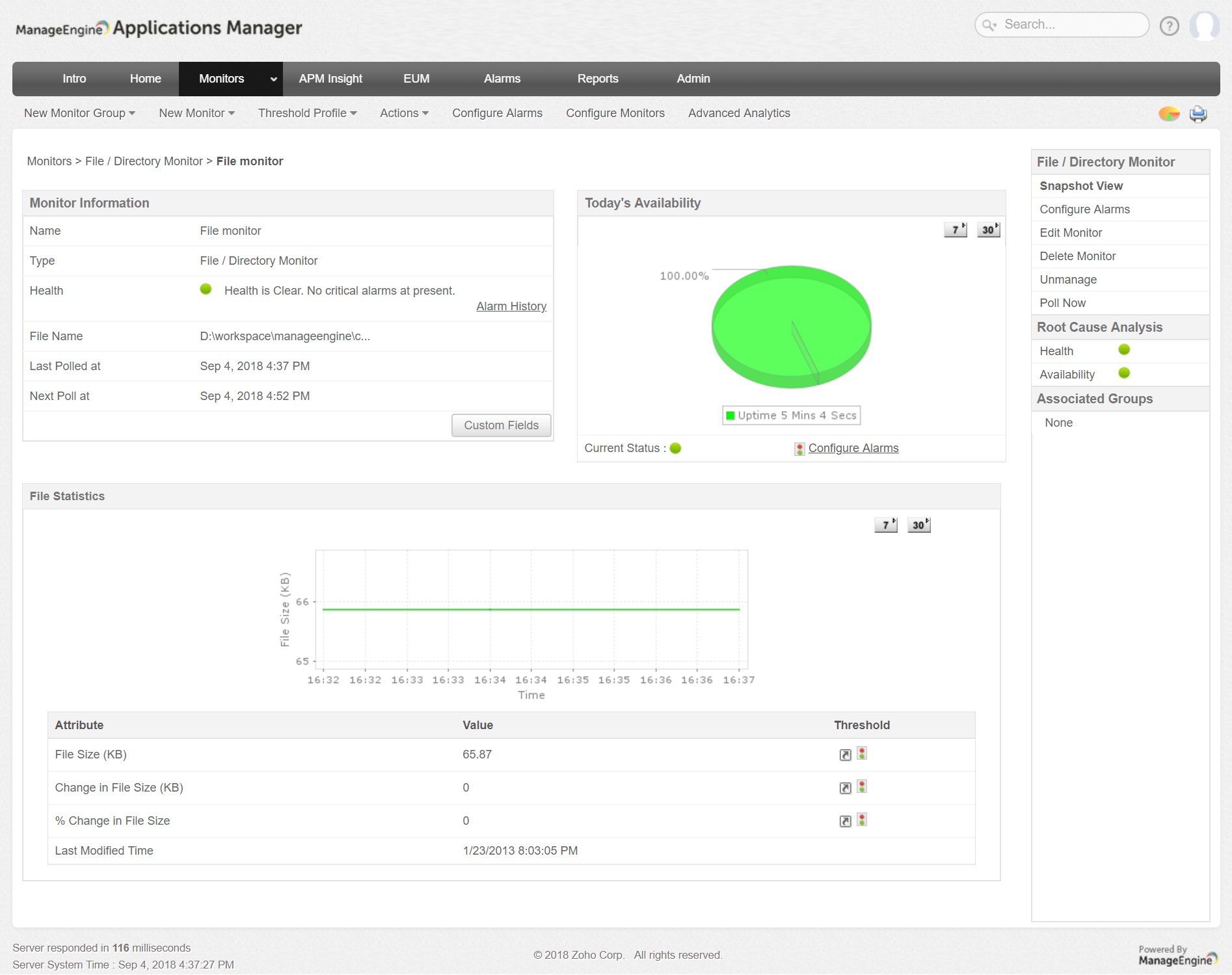

#Studio 5000 data file monitor how to#

In this article, you will learn what a FIFO is, how to set one up in Allen-Bradley’s Studio 5000 software, and how useful they can be. It is a great tool to have in your arsenal. Explore tutorials For Individuals CommunityĪt some point in your PLC Programming journey, you are likely to come across a FIFO, or to encounter a situation where using one would solve a problem. The logic, however, will remain the same. You can consult the official documentation to see the different syntaxes. The only difference will be a syntax specific to each language. Note that the package's operation of the package is the same regardless of the language used. For this example, we will use Python codes to communicate with a virtual PLC (PLCSim Advanced). It is an open-source package (or library) developed for several languages, such as VB, C++, Java, Python.etc, which allows us to communicate inherently via the S7 protocol (GET/PUT access).In this tutorial, you will learn how to use Snap7 to communicate with an S7 PLC. It has never been easier to communicate with PLCs or other industrial devices.If you wantwould like to develop a solution to communicate with a Siemens PLC, Snap7 is the ideal tool. Their adoption offers great flexibility when choosing equipment and dramatically facilitates communication between several different devices. Industrial Ethernet and other TCP communication protocols have become a standard in the industry.

0 kommentar(er)

0 kommentar(er)